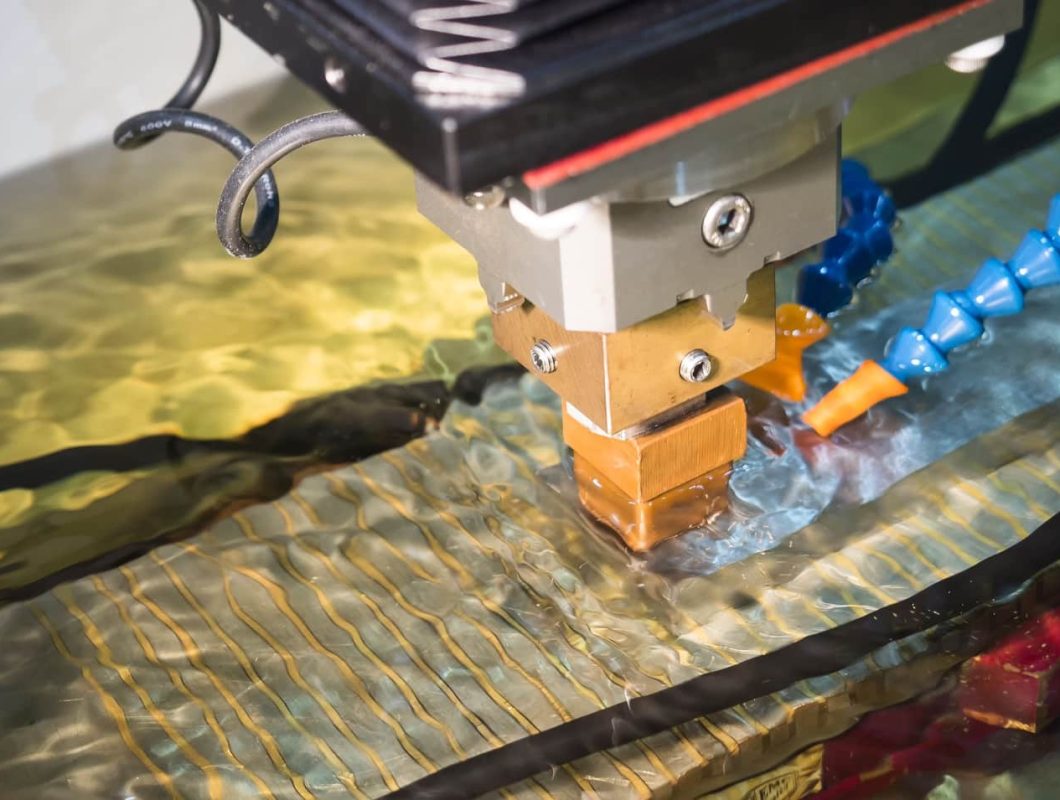

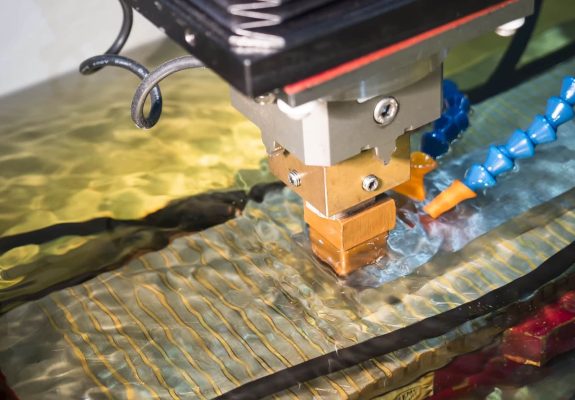

HMT has the latest Charmilles CNC Spark Erosion Machines at its disposal. These machines are able to work to 0.005mm tolerance and are extremely fast and reliable. Without a doubt, these machines provide the best quality erosion process available and can achieve finishes from a mirror finish (12VDI) to 45 or more VDI using copper, tungsten or graphite electrodes.

The Charmilles EDM uses 5 axis spark erosion allowing polished tunnel gates at any angle and deep slot eroding quickly and rapidly. Large areas are easily eroded giving a uniform finish without buring or leving hotspots.

Multiple electrodes can be used as the machines have electrode or tool changing carousels. Using the latest 3R holding/modular system, electrodes are machined in one setting giving greater accuracy and repeatability.

Due to the accuracy of our CNC milling machines we use less spark erosion these days. However, the exceptional levels of accuracy required by many of our customers mean that most of the moulds or tools we make will involve the use spark erosion at some point – usually in situations where the surface to be cut is not accessible to a normal milling machine.

Our engineers are able to control the electrical discharge machining (EDM) cutting process with great accuracy using our CAD 3D design software. As a result, even though this technique takes longer than conventional milling we are able to achieve it faster than our competitors, we need to do less EDM cutting than our competitors and CNC mill faster than they do. This is one of factors that enables us to make a tool in under half the time it takes our competitors.

Once the cutting is finished the tool is cleaned and polished ready for testing.

Spark erosion also known as EDM (electrical discharge machining) spark erosion is a machining method that is excellent for hard metals that cant be machined easily, or for small and intricate shapes or most commonly where a sharp corner is required. Spark erosion can cut cavities in pre-hardened metal without the need for heat treatment afterwards.

Spark eroding (EDM) is a method of removing material by a series of electrical arcing discharges (sparks) between an electrode (the cutting tool) and the workpiece. The EDM cutting tool moves along the desired path very close to the work but without touching it. The sparks emitted produce a series of craters on the work piece and remove material along the cutting path by “blasting” it away. These micro-craters result in the gradual erosion of the work piece to the shape of the cutting tool. The craters size and depth can be changed by altering the current (amps) and the on/off time of the current giving an array of different surface finishes available.